Your Address : Globalchemmade--Shachi Engineering Pvt. Limited

Name:Shachi Engineering Pvt. Limited

Type:Others

Tel:+(91)-(20)-25433786

Fax:+(91)-(20)-25433786

Email:info@shachidryers.com

Address:India

Equipents offer detail

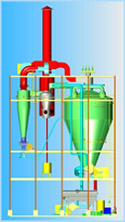

| Equipment: | Fluidized Spray Dryers |  |

| Equipment Type: | Drying Equipment -> Spray Dryer | |

| Unit Type: | ||

| Place Of Origin: | ||

| Price: | Inquire | |

| Valid Period: | ||

| Technical Parameters: | ||

| Usage: | ||

| Main Features: | Innovative spray drying chamber for efficient drying and long production time between CIP. Nozzle atomization for optimum spray of feed material . Choice of air distribution options for complete control of air flow . Choice of integrated, second-stage fluid bed options for drying or cooling . Third-stage, external fluid bed options for final drying and/or cooling . | |

| Description: | The Integrated Fluidized Spray Dryer combine spray drying and fluid bed drying technologies. Operational flexibility enables production of a wide range of physical properties and excellent thermal efficiency because drying at lower temperature. The spray is d by a spray nozzle atomizer down towards the fluid bed where agglomeration incorporating finer, recycled material takes place. Exhaust air outlet is let through the roof causing further agglomeration in the spray zone. The recirculation system uses cyclones or bag filters, or a combination of both to recycle fines to the spray dryer chamber, the integrated fluid bed, or the external fluid bed. The process produces non-dusty, free flowing agglomerated powders with high flavor retention. Third stage fluid bed drying / cooling can be done . Sticky products can successfully be dried, and the concept is ideal for drying heat sensitive products, and improved aroma retention is accomplished. This design concept is successful for drying high fats, hygroscopic, and sticky products that are difficult to handle in more conventional designs. | |